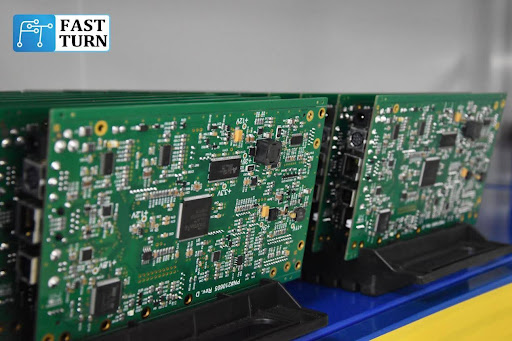

In modern electronics manufacturing, time, quality, and cost are everything. That’s why more product developers choose turnkey PCB fabrication and assembly — a one-stop solution where a single supplier manages the entire process, from raw PCB production to final functional testing. Instead of dealing with multiple vendors and long coordination cycles, engineers can upload their Gerber and BOM files once and receive fully assembled, ready-to-test circuit boards within days.

What Is Turnkey PCB Fabrication and Assembly?

Turnkey PCB fabrication and assembly means that a single manufacturer takes full responsibility for every stage of the project — PCB fabrication, component sourcing, SMT/THT assembly, inspection, and shipping. It’s called “turnkey” because the customer only needs to “turn the key” to start using the final boards.

Compared with traditional kitted or consigned assembly, turnkey service eliminates the need for customers to purchase and send components themselves. This reduces logistics complexity and ensures consistent quality across every build.

Why Choose a One-Stop Turnkey Electronic Assembly Service?

Time savings: Managing separate PCB, parts, and assembly suppliers requires significant coordination. With a turnkey partner, communication is streamlined, and project timelines are shorter.

Better quality control: A single manufacturer manages DFM (Design for Manufacturability), DFT (Design for Test), and all in-process inspections, including AOI, X-ray, ICT, and functional testing. This ensures each board meets design and reliability standards.

Cost efficiency: Because the supplier sources components directly from authorized distributors, material costs are lower, and procurement risks are reduced. Bulk purchasing also helps avoid costly shortages and delays.

The Turnkey Process: Step by Step

- File submission and review – The process begins when you upload Gerber, BOM, and pick-and-place files. Engineers review these documents for manufacturability and provide quick feedback and pricing.

- PCB fabrication – High-quality multilayer, HDI, or rigid-flex boards are produced under controlled processes. Surface finishes such as ENIG, HASL, or OSP are applied based on design requirements.

- Component sourcing – Parts are purchased from authorized global distributors. Substitutions are only made with customer approval. Shortages and alternates are communicated proactively.

- SMT and THT assembly – Components are placed using automated pick-and-place machines, soldered, and inspected. Fine-pitch BGA, QFN, and 01005 components are supported.

- Testing and inspection – Each board passes SPI, AOI, X-ray, and electrical testing. Functional and aging (burn-in) tests can be added if required.

- Packing and delivery – Finished PCBs are carefully packaged and shipped worldwide via DHL, UPS, or FedEx.

This full-cycle workflow minimizes errors and shortens lead times, making it ideal for both prototypes and production runs.

Full vs. Partial Turnkey Assembly

Full Turnkey means the manufacturer handles everything — PCB fabrication, component sourcing, and final assembly. This model offers the fastest turnaround and a single point of responsibility.

Partial Turnkey (or Kitted Assembly) lets customers provide some or all components. It gives more control over specific parts but requires close coordination on logistics and inventory.

For most small- to mid-volume projects, full turnkey assembly offers the best balance of speed, cost, and reliability.

Full Turnkey PCB Assembly for Medical Electronics

Medical devices require extreme reliability and traceability. When choosing a full turnkey PCB assembly for medical electronics, it’s essential to work with a manufacturer that holds ISO 13485 certification and follows strict documentation control.

Fast Turn PCB, for example, provides medical-grade turnkey assembly with process traceability, component lot tracking, and record retention. Each step — from material handling to testing — is verified and logged.

The boards use low-residue and lead-free soldering processes to meet biocompatibility and cleaning standards. Functional, in-circuit, and aging tests ensure long-term stability and performance in critical healthcare applications.

Factors That Affect Lead Time and Cost

- Design complexity – Layer count, blind or buried vias, HDI features, or impedance-controlled traces can add time.

- Component availability – BOM items with long lead times or obsolete parts can cause delays; early sourcing helps mitigate them.

- Testing requirements – ICT, FCT, or custom fixtures add setup time but improve reliability.

- Batch size and urgency – Prototype orders may take 3–7 days; full-production runs vary by volume and materials.

To keep your project on schedule, always review design for manufacturability (DFM) before submitting files and confirm any substitute parts in advance.

Manufacturing and Quality Capabilities

A professional turnkey provider like Fast Turn PCB combines advanced fabrication and assembly under one roof:

- PCB manufacturing up to 50 layers, including HDI, rigid-flex, heavy copper, and high-frequency designs.

- Assembly precision for BGA, QFN, CSP, LGA, and micro components down to 01005.

- Quality assurance with AOI, X-ray, ICT, and functional testing to IPC Class 2 or Class 3 standards.

- Certifications include ISO 9001, ISO 13485, UL, and RoHS/REACH compliance.

These capabilities make turnkey production suitable for demanding industries like medical, aerospace, industrial control, and telecommunications.

Pre-Order Checklist: What to Prepare

Before requesting a quote, make sure you have:

- Gerber files for PCB layers and drill data.

- BOM file with clear part numbers, package types, and approved alternates.

- Pick-and-place (CPL/XY) file and assembly drawing.

- Quality requirements such as inspection level or special certifications.

- Shipping and build preferences (e.g., box build, partial shipment).

A complete, clear documentation package helps engineers review and quote your project more quickly.

Conclusion

Turnkey PCB fabrication and assembly simplifies electronics production by combining fabrication, sourcing, assembly, and testing into one efficient workflow. Engineers save time, reduce risk, and gain consistent quality from prototype to production.

Whether you’re developing IoT devices, industrial controls, or medical instruments, a reliable turnkey electronic assembly service ensures your design moves from file to functional product faster.