In today’s fast-moving electronics market, time, quality, and cost control determine success. That’s why more companies choose one-stop PCB assembly — a complete solution that includes every step from PCB fabrication to final testing and packaging. Instead of dealing with multiple vendors, you work with a single turnkey PCB assembly manufacturer that takes full responsibility for the project.

Fast Turn PCB based providers specialising in full turnkey services, from prototypes to low- and medium-volume production. This guide explains what one-stop PCB assembly means, what it includes, and how it helps engineers manage even complex multi-layer boards with confidence.

What Is One-Stop PCB Assembly?

A one-stop PCB assembly service covers the entire production flow: design for manufacturability (DFM), PCB fabrication, component sourcing, SMT/THT assembly, inspection, testing, and shipping. Everything happens under one management system and quality standard.

Compared to managing separate suppliers, a one-stop partner provides faster turnaround, better communication, and lower hidden costs. It also ensures traceability, consistency, and accountability from start to finish.

One-Stop vs. Turnkey PCB Assembly

In the industry, “one-stop” and “turnkey” PCB assembly are often used interchangeably, but there are subtle differences: a one-stop service covers all processes under one roof, while turnkey typically emphasises the manufacturer’s responsibility for sourcing all materials and handling logistics. This distinction is important when evaluating service models.

- Full Turnkey: The manufacturer handles everything, including material sourcing and logistics.

- Partial Turnkey: The customer provides some or all components, while the factory manages fabrication and assembly.

If you’re developing new products, prototypes, or small-batch production, full turnkey is usually the best option. It reduces risk, simplifies project control, and guarantees that all materials are verified for compatibility and quality.

What’s Included in One-Stop PCB Assembly

A reliable turnkey PCB assembly manufacturer offers the following full range of services:

- Design & DFM/DFA Review – Engineering teams check Gerber files, stack-up, BOM, and placement data to ensure manufacturability and cost efficiency.

- PCB Fabrication – Single- to multi-layer, HDI, impedance-controlled, and special surface finishes like ENIG or immersion silver.

- Component Sourcing – Full BOM matching, alternatives for obsolete or long-lead parts, and verified global component sourcing.

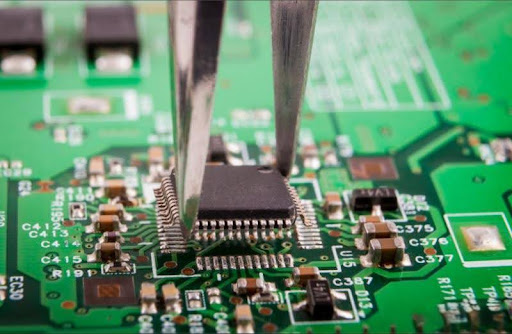

- Assembly – High-precision SMT, THT, selective soldering, and cleaning, capable of handling 01005 passives and fine-pitch BGAs.

- Testing & Programming – AOI, X-ray, flying probe, ICT, and functional testing ensure every board meets performance specs.

- Packaging & Delivery – ESD-safe packing, labelling, and documentation for traceable delivery.

Full Turnkey PCB Assembly for Complex Multi-Layer Boards

Modern electronics often rely on complex multi-layer PCBs with HDI structures, blind and buried vias, and high-speed signal integrity requirements. Managing such builds requires strong engineering, process control, and inspection.

Fast Turn PCB supports multi-layer boards up to 40 layers with advanced materials such as Rogers and hybrid FR-4/PTFE laminates. Precise impedance control, X-ray inspection for BGAs, and AOI coverage for fine-pitch devices ensure consistent quality.

For high-frequency and high-density designs, DFM analysis is critical. A one-stop partner provides early feedback on stack-up design, copper balance, and thermal management — preventing issues like warpage, signal loss, or poor solder joints later in the process.

Turnaround Time and Capacity

Engineers prefer one-stop PCB assembly for its significantly reduced lead time, thanks to the integrated processes.

Typical examples include:

- Prototype: as fast as 24 hours

- Small-batch production: within 3–5 days

- Mass production: depends on component lead time and test complexity

With manufacturing, sourcing, and assembly on one schedule, waiting between stages is eliminated. This makes one-stop assembly ideal for startups, validation, and fast project launches.

Quality Standards and Certifications

A trustworthy turnkey manufacturer should follow international standards and hold the right certifications. Fast Turn PCB is certified to ISO 9001, ISO 14001, ISO 13485, IATF 16949, and UL. All assemblies meet IPC-A-610 Class 2 or Class 3 workmanship levels.

The company also applies Six Sigma and SPC process control, maintaining data for CPK performance and yield analysis. Quality reports, FAI records, and traceability labels are available with every shipment. This level of control helps customers meet regulatory and reliability requirements for medical, automotive, and industrial electronics.

What to Prepare Before Ordering

Before requesting a quote or placing an order, make sure your production files are complete and properly named. A typical documentation package includes:

- Gerber or ODB++ files

- Bill of Materials (BOM) with part numbers and replacement rules

- Pick-and-Place coordinates and assembly drawings

- Test requirements or firmware for programming

- Special process notes (e.g., controlled impedance, conformal coating)

- Engineering Change Notes (ECN) or revision history

Providing clear, up-to-date data helps your manufacturer deliver accurate pricing, smoother DFM review, and faster turnaround.

How to Choose the Right Turnkey PCB Assembly Manufacturer

When comparing one-stop assembly providers, consider these key factors:

- Engineering Support: Fast and detailed DFM feedback, ability to solve design or manufacturing issues early.

- Production Capability: Advanced SMT lines, HDI/microvia capability, and fine-pitch BGA handling.

- Quality Control: ISO and IPC compliance, full inspection coverage (AOI, X-ray, ICT).

- Supply Chain Strength: Stable sourcing channels and substitute component databases for risk control.

- Responsiveness: Quick communication, clear project milestones, and real-time updates.

A professional partner like Fast Turn PCB provides transparent data, technical support, and flexible production — ensuring a smooth transition from prototype to mass production.

Final Thoughts

Choosing a professional turnkey PCB assembly manufacturer like Fast Turn PCB means you can focus on design and innovation while your partner handles fabrication, sourcing, assembly, and testing under strict quality control.

If you’re preparing for your next project, organise your design files and BOM, then request a DFM review or instant quotation. One-stop PCB assembly is not just about convenience — it’s about building better boards, faster, and with greater reliability.